I’m a mechanical engineer and I design industrial packaging equipment. I graduated in 2015 with my S.B. in MechE from MIT. I’m a renaissance woman – I love when I get the opportunity to pick up something new. The best innovations come from cross-disciplinary collaboration, and having varied interests puts me in a good position to contribute to meaningful projects. From a family of teachers, I’m passionate about STEM education and love teaching and developing STEM outreach programs in the community. I’m especially proud of developing the K-12 Academy for TechWorks of Gaston County, more info here!

I’m also a competitive masters rower, former college volleyball player, and aspiring gravel cyclist. I love fixing boats and messing with bikes and have a laundry room that most people would call a “mini machine shop” more than place for folded clothes.

Engineering Experience

Sealed Air Corporation, June 2015 - Present

Senior Mechanical Engineer, Innovation and Development - Industrial Automation and Robotics Team

Mechanical Engineer, Innovation and Development - Industrial Equipment, Automation, and Protective Packaging Teams

Associate Mechanical Engineer, Technical Leadership Rotation Program

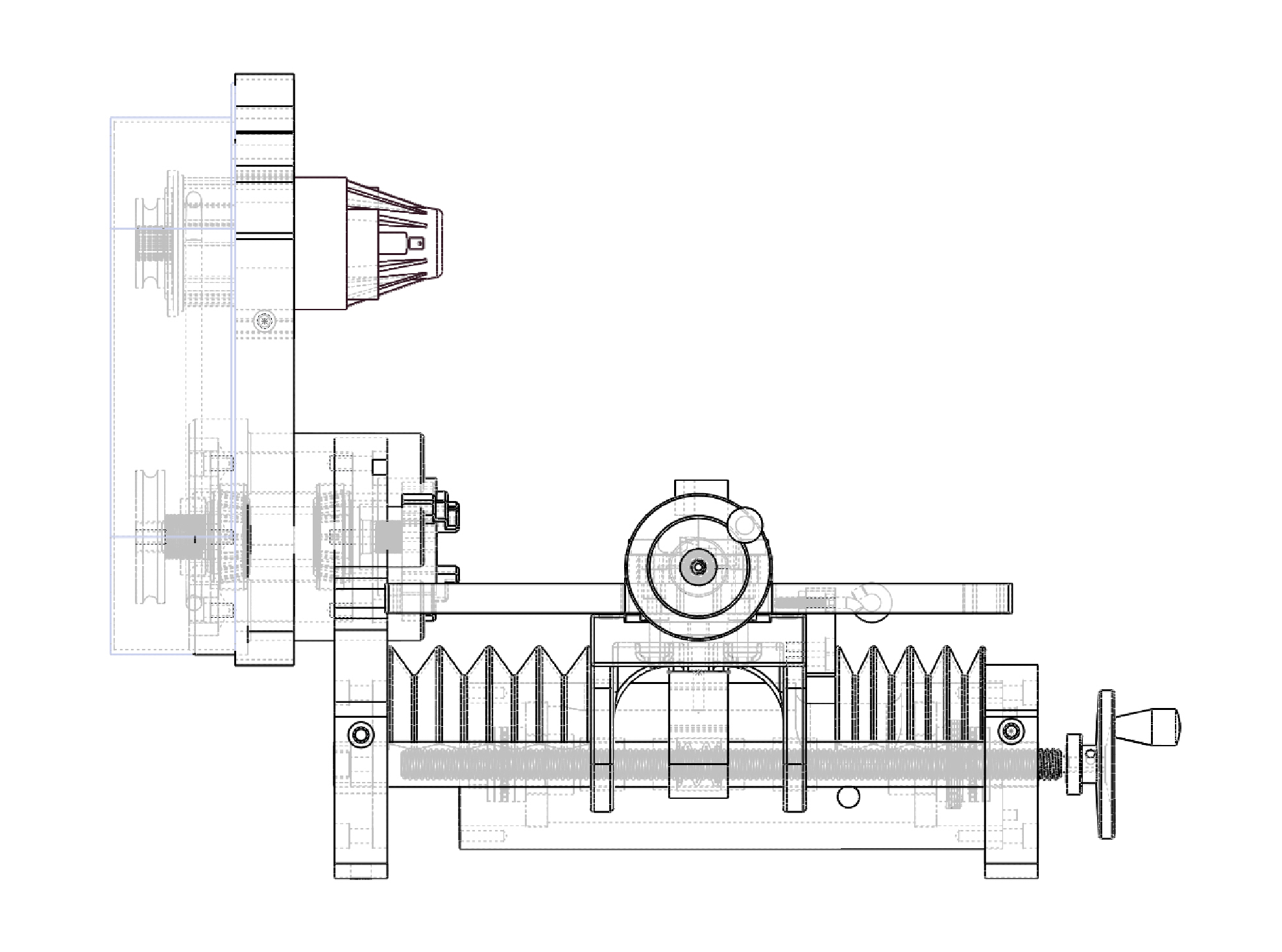

Most of my work at Sealed Air has been in early stage machine and process development, so not all of the projects that I am most proud of are publicly available or commercialized yet. However, here are some representative products, projects, and machines that I have worked on or served as the inspiration for the next generation design that is soon to come!

I come to work every day to solve tough problems and inspire teams to develop new equipment, products, and processes. I am proud that my team chooses to come work in the office because of the collaborative and trusting culture that we have built. Together, we know how and why machines work (and don’t) and design solutions that reduce operator labor, improve safety, and increase throughput.

I design industrial machinery for production facilities to take raw and converted materials, and transform them into the packaging materials that protect products from production to your doorstep. I also develop hygienic equipment for packaging the food we eat every day.

I also program industrial robot arms and design simulations to assist in the integration of robotic solutions for food packaging facilities

Internships

Battelle Memorial Institute, Mechanical and Manufacturing Engineer Intern

Summer 2012, 2013, 2014

As an intern at Battelle I first worked as a manufacturing engineering intern in their Production and Field Support low-volume manufacturing facility. I designed custom workstations for build cells and learned about various electronic production processes. I also developed a software tool to implement a paperless build instruction procedure on the plant floor, with integrated revision and quality control.

I then worked in Tactical Systems, developing test fixtures, test plans, and running customer support lines during a product trial. Finally, I designed parts as a mechanical engineering intern in Medical and Consumer products, helping to bring a new pumping system from idea to functional prototype by the end of my summer term.

InterestS

Machine Design

3D Modeling

Hardware Design

Python

Maker Education

Composite Boat Construction

Competitive Rowing

Gravel Cycling

Mini-Internships:

Mechanical Engineer, Soofa, Fall 2014

Mechanical Engineering Intern, 5 Wits Productions, January Term 2013

CLASSROOM Experience

DIRECTOR, K-12 PROGRAMMING, TECHWORKS OF GASTON COUNTY

April 2019 - April 2020 (COVID)

MIT Edgerton Center, OUTREACH TEACHING ASSISTANT

Fall 2012 - Spring 2015

DYNAMIT, MENTOR

Summer 2013, Summer 2014